If you're like most people, you're probably still getting your head around the idea of 3-D printing. That's where a printer head, directed by a digital blueprint, sprays successive layers of material on top of one another to create a solid three-dimensional object. But even as that technology rapidly catches on in fields ranging from aerospace to dentistry, scientists have come up with something that's even wilder to contemplate: 4-D printing, in which a printer creates objects that are programmed to shape-shift as time passes, or in response to certain stimuli.

A number of researchers have been working on 4-D printing technology. Now, a team of scientists from Harvard University's Wyss Institute for Biologically Inspired Engineering and the school's John A. Paulson School of Engineering and Applied Sciences (SEAS), led by Wyss core faculty member Jennifer A. Lewis, have come up with yet another breakthrough. In an article published in Nature Materials, they describe a new, more streamlined process, inspired by plants' changes in response to stimuli such as light, humidity or touch.

Advertisement

Entering the Fourth Dimension

The concept of 4-D printing was first developed by a Massachusetts Institute of Technology team led by research scientist Skylar Tibbits. Tibbits is co-director of the school's Self Assembly Lab, which works on devising ways to get materials to organize themselves into objects. As this 2013 Technology Review article details, Tibbits and his colleagues took a new flexible material developed by an Israeli company, Stratasys, which expands to 150 times its volume when placed in water, and combined it with a second, more rigid material.

They then used software to determine the exact ratio and optimal orientation to use in combining the two materials so that when introduced to water, they would bend and reshape themselves into a new configuration. During a 2013 TED talk (watch it below) Tibbits unveiled the 4-D process and created a sensation dipping a strand of the material into water and showing how it shifted shape into the letters MIT.

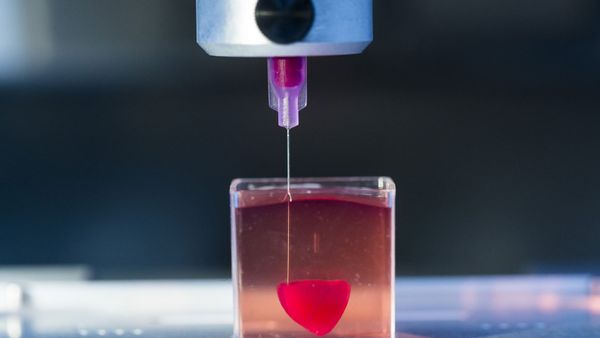

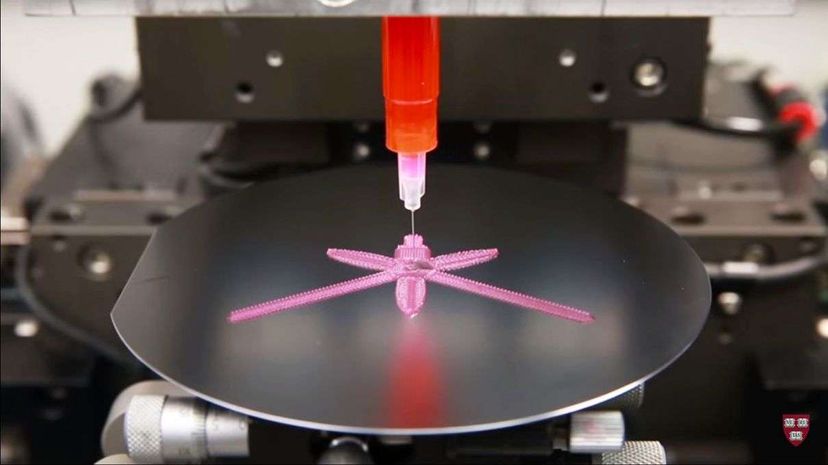

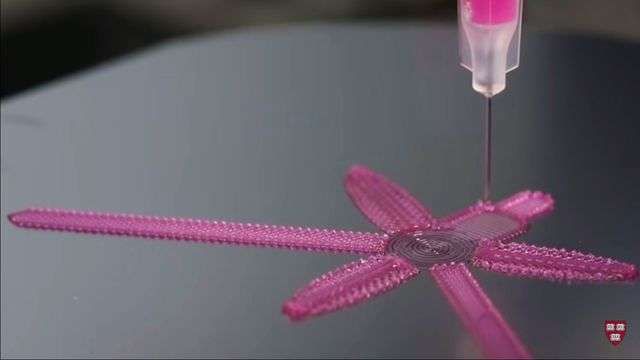

In contrast to the two-material process devised by MIT, the Harvard team utilizes just one material — a composite gel ink with tiny fibers of cellulose, a component of the cell walls in plants, spread around inside it. After the material is sprayed by a printer to form an object, the real fun begins. If you haven't yet, watch the Harvard video at the top of this article to see the printer create a flower shape that expands and changes in water.

Inspiration From Nature

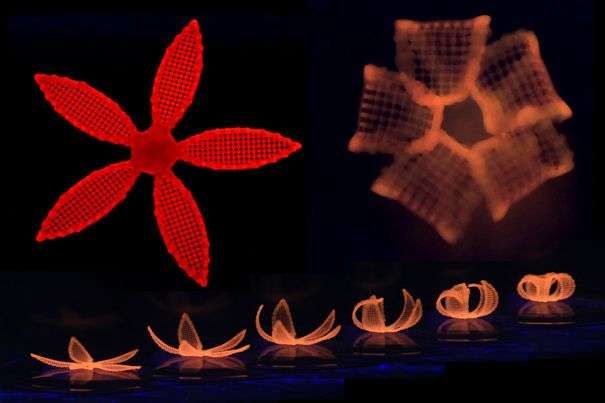

One of the study's co-lead authors, Harvard graduate student A. Sydney Gladman, explains via email that the new 4-D printing process was inspired by nature and mimics a phenomenon called anisotropic swelling, in which some parts of a plant swell more in one direction than another. She cites the example of pine cones, which remain closed when they're in a hydrated state on a tree, but then open up when they dry out on the ground in order to disperse seeds. Some flowers change in response to stimuli though this phenomenon as well.

"We are mimicking exactly this mechanism by embedding the same cellulose fibrils in our hydrogel composite ink," says Gladman. "During printing these fibrils align, which causes the printed filaments to swell more in one direction than the other."

By laying down the cellulose fibers at precise angles, it's possible to dictate how the material will reform itself into complex shapes when exposed to water. "When one angle is 0 degrees and one is 90 degrees you get bending behavior," says Gladman. "When one angle is 45 degrees and the other is [negative] 45 degrees, you get twisting behavior."

While more work must be done to turn 4-D printing into a practical-to-use technology, there are tons of potential uses, such as smart textiles that could change shape as needed (imagine Marty McFly's self-adjusting clothes in "Back to the Future II") and soft electronics . Gladman says the researchers are also investigating the eventual use of 4-D printing for transformable tissue engineering, in which cells would be sprayed on a scaffold to create artificial transplant organs that might grow or change as the body needs it. Someday, that might make many of us into shape-shifters.

Advertisement