Few argue that the next generation of computers will be nearly invisible, meaning that they will blend in with everyday objects. Flexible ink-like circuitry will be printed onto plastic or sprayed onto various other substrates, such as clothes. One of the scientists leading this printable computer revolution is Joseph Jacobson of MIT Media Lab's Nano Media Group. Jacobson has said that his group will be able to produce a simple printed microprocessor in late 2001 or early 2002. He also foresees being able to eventually produce a printed chip that could rival an Intel Pentium processor.

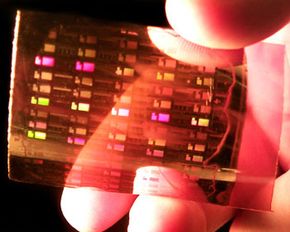

Jacobson's group has already succeeded in using an ordinary Hitachi ink jet printer to make several components for a printable computer. Using a nanoparticle-based ink made from suspending nano-size semiconductor particles in a liquid, researchers spray the components onto a plastic substrate. Here's a look at some of the printed components the MIT group has made with this process:

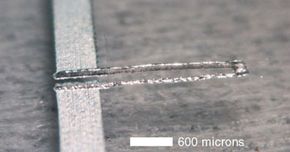

- Thermal actuators -- An actuator is a sensor that causes a device to be turned on, off, adjusted or moved. In a thermal actuator, heat is used to cause the expansion of components to create movement.

- Linear-drive motors -- This type of motor is similar to a normal electric motor, which has a magnet that circles around the coil loop to make the motor spin. However, there is one key difference. Think of linear-drive motors as flattened electric motors containing a flat magnet moving back and forth across a coil. In a sense, the magnet in the linear drive motor acts like a piston.

- Microelectromechanical Systems (MEMS) -- MEMS are touted as the precursor or bridge to nanotechnology. These micromachines are used in a variety of devices, including pacemakers, games, and accelerometers of airbags. They perform a variety of functions, including sensing, communication and actuation. In the future, MEMS are expected to have the ability to self-replicate.

The Media Lab also created transistors using a different process. For that, polymer stamps are used with the architecture of the transistors in a positive relief. The stamp is then dipped in the nanoparticle ink and transferred to a substrate by hand. The next step will be to use an ink jet printer or some other kind of desktop fabricator to create printable transistors.

MIT isn't the only group developing ways to print computer circuitry. Plastic Logic, a company that sprang out of work begun at Cambridge University in England, plans to market the first plastic chip. The company has developed and patented a method of printing plastic onto polymer substrates, making cheap and flexible plastic transistors. The process is similar to the ink jet process used by MIT, but Plastic Logic adds carbon-based chemicals to alter the properties of the plastic. By printing the chips onto rolls of film, they can be applied to a variety of surfaces.

At Lucent Technologies' research company, Bell Labs Innovations, researchers developed the world's first printed transistor in 1997. Using plastic sheets similar to overhead projector transparencies, a liquid plastic semiconductor is applied over a stainless-steel mesh with a squeegee to form the multiple layers of the transistor. After the solvent of the mixture evaporates, the plastic remains. The process is very similar to how silk screening works. Lucent has teamed up with E Ink, an MIT offspring, to create printable displays. See How Electronic Ink Will Work for more information.

Soon, scientists will be able to create just about every part of a computer's hardware using a desktop fabricator. Plastic will take the place of silicon for many purposes, but don't expect to write off silicon as a valuable computer component for at least a decade or two. In the next section, we'll see how plastic stacks up against silicon and why we can expect silicon to stick around for many more years.